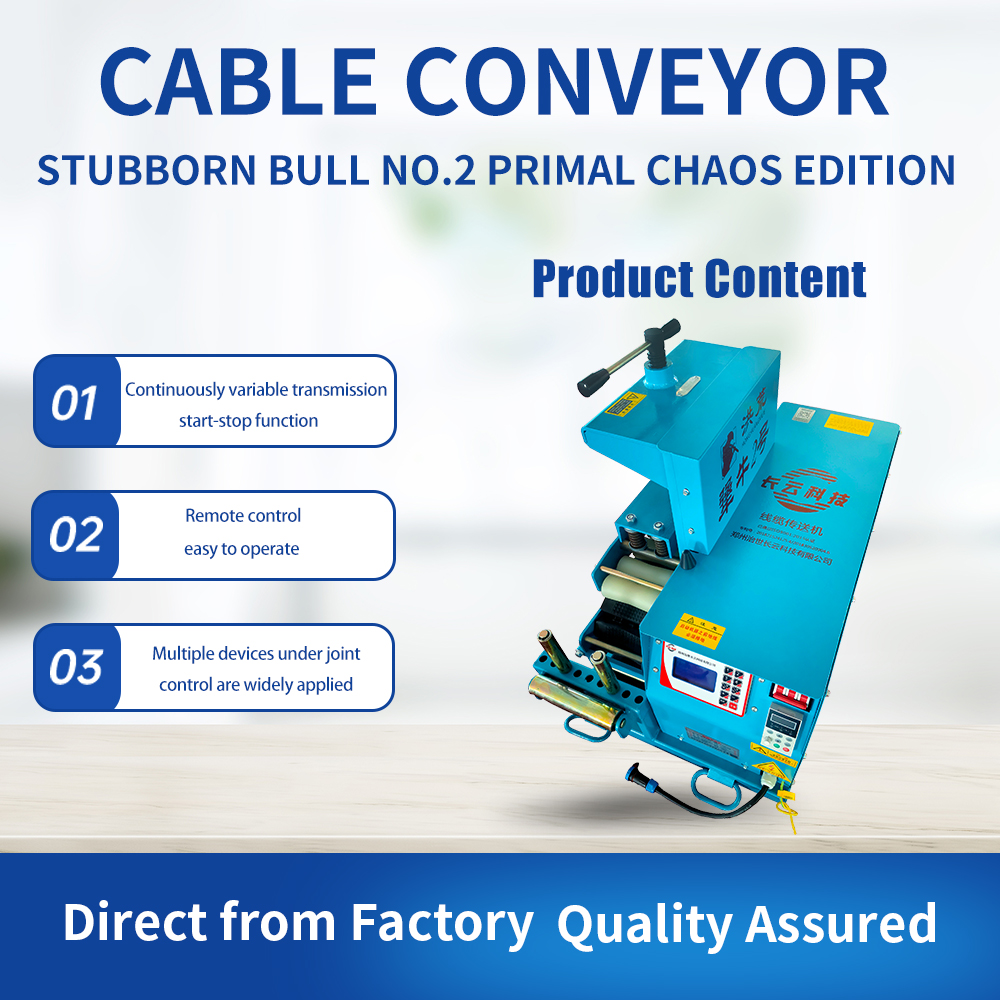

Product Content:

Continuously variable transmission, start-stop function

Remote control, easy to operate

Multiple devices under joint control are widely applied

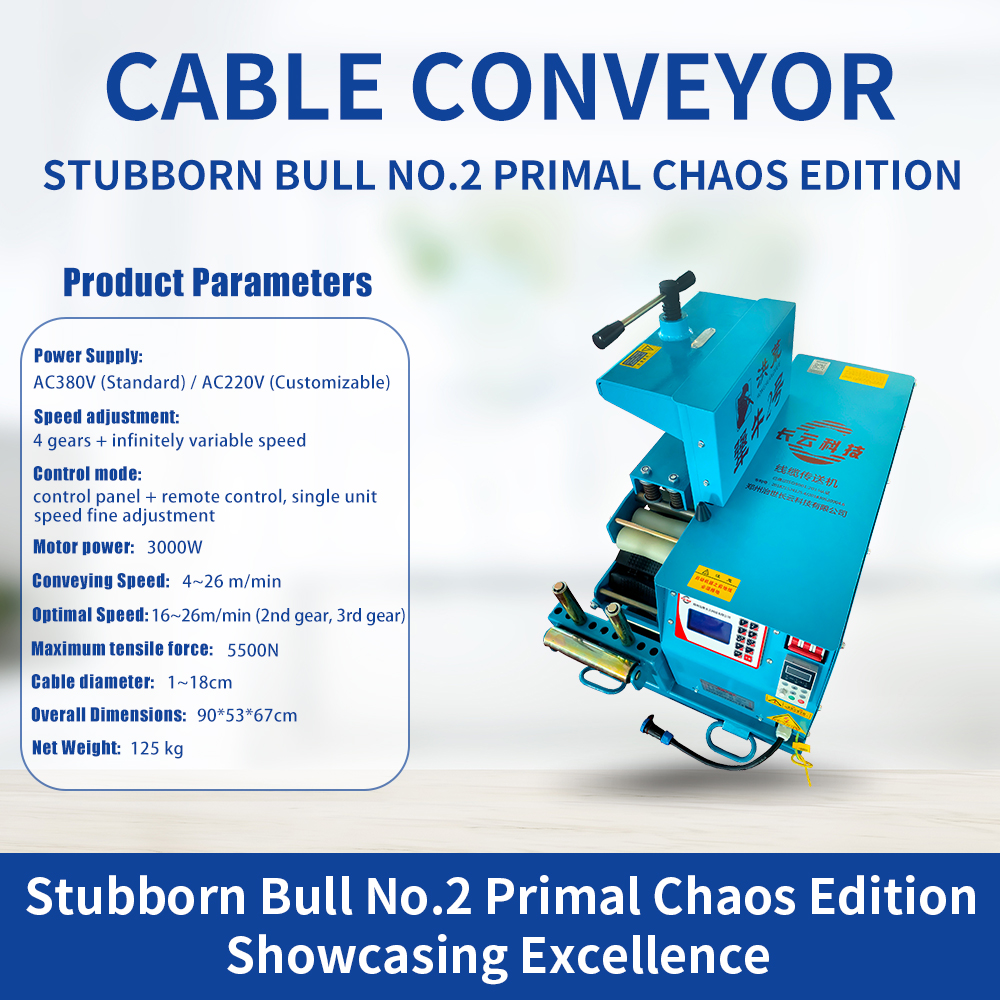

Product Parameters:

Power supply: AC380V (standard), AC220V (customizable)

Speed adjustment: 4 gears + infinitely variable speed

Control mode: control panel + remote control, single unit speed fine adjustment

Motor power: 3000W

Conveying speed: 4~26m/min

Optimal speed: 16~26m/min (2nd gear, 3rd gear)

Maximum tensile force: 5500N

Cable diameter: 1~18cm

Overall dimensions: 90*53*67cm

Net weight: 125kg

Product Description:

This machine is compact, lightweight, small in size, efficient, and easy to move, making it suitable for laying cables over long distances in confined spaces, such as tray cables, cables in subway tunnels, instrument cables, and electrical control wires.

This machine boasts a reasonable structure, excellent performance, stable operation, low noise, low power consumption, fast conveying speed, and simple and convenient maintenance.

This machine can operate in both "forward" and "reverse" directions, with 4 main speed settings, and can also achieve stepless speed adjustment using "+ " and "-". The machine and remote control can be used in frequency modulation groups without interfering with each other. It also has multi-unit remote control functionality, enabling long-distance control.

Product Features:

Small size, light weight, easy to handle

Remote control, easy to operate

Four-speed infinitely variable transmission, one-button push-pull switching

Nylon pressure wheel combined with high-quality rubber wheel design ensures long service life

Product Packaging & Shipping

We ensure your machinery arrives in perfect condition, ready for immediate use, through robust packaging and flexible shipping solutions.

1. Packaging Methods:

Standard Export Wooden Cases: Each machine is securely fixed within a custom-built crate, which is specifically designed to prevent damage from moisture, impact, and rough handling during long-distance transportation.

Comprehensive Internal Protection:

Machines are first wrapped in heavy-duty plastic film for moisture and dust protection.

They are then secured inside the cases using high-strength straps and foam padding to eliminate any movement.

All accessories, remote controls, and documentation are individually packaged and sealed within the main wooden case.

Clear External Marking: Cases are clearly labeled with:

Product Name & Model

Gross/Net Weight

Package Dimensions (L x W x H)

Handling Instructions (e.g., "Fragile," "This Side Up," "Keep Dry")

Your unique order number for easy identification.

2. Shipping Methods: (e.g., Deppon Logistics)

We offer various shipping options to best suit your timeline and budget:

Rail Transport: Railway transportation offers stable transit times and is unaffected by weather, providing reliable logistics support for your foreign trade orders.

Sea Freight (FCL/LCL): We tailor the most economical solutions for each buyer order.

Air Freight: To expedite urgent or small-volume orders, we coordinate with air carriers to ensure timely delivery.

After-Sales Service & Support

1. Warranty Policy

We provide a standard warranty period of 12 months commencing from the date of delivery.

The warranty covers all manufacturing defects and malfunctions under normal operating conditions.

During the warranty period, any product-related issues will be evaluated on a case-by-case basis, and necessary support and services will be provided.

2. Global Technical Support

Lifetime Free Consultation: We offer free, lifelong technical consultation via email, WhatsApp, and WeChat. Our engineers are readily available to answer any operational or technical inquiries you may have.

Remote Diagnostics: For specific issues, our technical team can provide remote guidance and troubleshooting through online video calls.

3. On-Site Service

For complex issues that cannot be resolved remotely, we can arrange for certified engineers to provide on-site service. This service includes:

Equipment installation, commissioning, and calibration.

On-site operation and maintenance training for your personnel.

Thorough inspection and repair.

Delivery Details:

Method: By sea or air freight.

Delivery: Within 3 days of payment receipt.

Packaging: Standard export wooden crates with waterproof lining and foam padding for fixation.

Tracking: Shipping documents & tracking number provided via email.

Company Information:

Zhengzhou Zhi Shi Changyun Technology Co., Ltd., established on June 30, 2014, is a comprehensive enterprise integrating R&D, manufacturing, and sales. Its business spans machinery manufacturing, communication equipment, and engineering machinery, with main products including cable conveying machines, Optical Cable Pulling Machines, and winch grinders, among other professional equipment. The company operates a modern production facility covering 6,000 square meters and employs over 150 technical professionals. It has obtained ISO9001 quality management system certification and nearly 100 patent grants. Its products are widely used in power engineering, communication networks, transportation infrastructure, and other fields, with a nationwide sales and service network. The company provides a year-round 24/7 telephone consultation service, and its technical team can respond to on-site issues within 48 hours. In 2023, it was recognized as a High-Tech Enterprise in Zhengzhou and has maintained the title of "Contract-abiding and Credit-worthy Enterprise" for five consecutive years (2020-2025).

Product Case:

"Stubborn Bull No.2 Primal Chaos Edition Cable conveyor Tunnel Construction"

In the electric power tunnel project, the Changyun Technology Jiangniu No.2 Honghuang version cable conveyor successfully completed a highly challenging laying task. Faced with the laying of a 1.2-kilometer-long, 300-millimeter-diameter high-voltage cable, this equipment demonstrated excellent performance. It steadily advanced at a speed of 15 meters per minute, significantly reducing the construction period, and the quality of the laying was also very high!

The project leader stated, "The tunnel environment is complex, and traditional equipment is prone to slipping and getting stuck. The 'Jiangniu 2 Honghuang version' ensures continuous and stable traction in wet and slippery environments, with zero damage to the cable's outer sheath." The excellent performance of this equipment provides a reliable technical solution for similar large-scale cable laying projects.

Frequently Asked Questions:

Q: Is this machine complicated to operate? Can our current workers quickly get started? Is maintenance troublesome in the later stages?

A: Please rest assured, we have fully considered the actual situation on the construction site. The operation is very intuitive. The equipment adopts a dual mode of user-friendly control panel and remote control, and ordinary workers can operate it independently after simple training from us. Regarding maintenance, the equipment adopts a modular design, and key components such as the track are easy to replace. Routine maintenance only requires checking lubrication and cleaning dirt. We provide detailed maintenance manuals and guidance.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

يستخدم هذا الموقع ملفات تعريف الارتباط لضمان حصولك على أفضل تجربة على موقعنا.